About New Ancorvis

A leader of digital technologies applied to the dental sector, New Ancorvis has experienced a strong technological development since early 2000, which has allowed it to stand out on the dental market as an ideal and trustworthy partner for the operators of the industry, expanding the range of solutions offered in the dental and prosthetic sector…

There is something special in the air when we create solutions to offer to our customers and we enter the market in a progressive and modern way showing our digital DNA.

Index

The Company

The constant update of technology has encouraged New Ancorvis to build very high-speed machining centers to ensure precision parts, automation and safe processes.

All of our products are subjected to tests and conformity checks which guarantee quality, safety and reliability.

Our Values, Our DNA.

A leader of digital technologies applied to the dental sector, New Ancorvis has experienced a strong technological development since early 2000, which has allowed it to stand out on the dental market as an ideal and trustworthy partner for the operators of the industry, expanding the range of solutions offered in the dental and prosthetic sector…

There is something special in the air when we create solutions to offer to our customers and we enter the market in a progressive and modern way showing our digital DNA.

Our mission is aimed at enhancing the complementarity of clinical, technical and industrial know-how to generate more value!

Single Elements and Customised Abutments

Individual abutments and single elements available for both cement-retained technique on Ti-base and screw-retained technique across all implant platforms available on the market.

Materials: Titanium gr 5 / Cromo-Chobalt

Workflow: Digital / Analogue

Variants: straight, angled

CAD libraries available for popular software: Exocad, 3Shape, and Dental Wings.

Available in the following versions:

- Milled Technique: Ensures optimal precision.

- Hybrid Technique – M2 Line: A hybrid technique that combines the benefits of additive manufacturing (Selective Laser Melting) with selective milling in critical areas such as the prosthetic screw seat, implant connection, and transmucosal height.

- Hybrid Technique – MBase Tech:

- Thanks to a patented hybrid production protocol, we are able to produce custom abutments and screw-retained single crowns using additive manufacturing technology (selective laser melting) over a pre-machined base (obtained by turning).

Maximum precision in the implant connection, total respect of the anatomies in the body of the prosthesis.

Free CAD Libraries Multilingual Support for Installation and Use

Screws included

Multi Unit Abutments

New Ancorvis MUAs stand out for their quality and extensive range.

- CE Marked: Ensuring compliance with safety and quality standards

- Compatibility: Compatible with most implant platforms

Technical Data Sheets: Implant passports and technical sheets available for download from New Ancorvis dedicated online shop.

M.U.A. Slim Fit

Anatomically smaller and narrower : diameter 4.1 mm

Different transmucosal heights and inclinations: 0° -17°- 30°, characterised by an anti-rotation system.

Includes a prosthetic screw with M 1.6 threading, upgraded from the standard M 1.4, allowing for a tightening torque of 25 Ncm, delivering enhanced stability.

Perfectly integrated on our digital workflows (including INNOVA System), it features a set of scanbodies, digital analogues and implant CAD libraries.

Clinical Benefits:

- Reduced biological footprint for better management of subcrestal implants.

- Promotes a biological seal without interfering with peri-implant tissues.

- Ideal for direct screw-retention in zirconia, including single units.

Materials: Ti gr 5

Workflow: Digital / Analogue

Warranty: Lifetime

Variants: Straight, Angled

Free CAD Libraries Multilingual Support for Installation and Use

Screws included

Fast Service: same-day shipping

Implant Bridge and Toronto Bridge

Our production workflow, with guarantees of predictability and repeatability, makes these processes easy to use and accessible to everyone.

Key indications: Screw-retained prostheses on implants

Material: Zr | ZT | Ti | ceramic Cr-Co | PEEK | multilayer PMMA | Fiber glass

Workflow: Digital / Analogue

- Milled Technique: Ensures optimal precision.

- Hybrid Technique – M2 Line: A hybrid technique that combines the benefits of additive manufacturing (Selective Laser Melting) with selective milling in critical areas such as the prosthetic screw seat, implant connection, and transmucosal height.

Free CAD Libraries Multilingual Support for Installation and Use

Screws included

Aesthetic Duo

Product Description

- Primary bar* screw-retained into implants Tigr5 and Cr-Co Selective Laser Melting, with mucosal support and post-machined implant connections;

- Milled secondary structure in zirconia, PMMA, composite or prototyping resin for testing.

IN-HOUSE solution available

Splitting file (free of charge)

CAD libraries

CORE file for secondary structure

Color Anodisation

●

●

*Primary Bar is always manufactured by New Ancorvis

Free CAD Libraries Multilingual Support for Installation and Use

Screws included

IN-HOUSE Solution

Gemini Line

You can request a customized component tailored to the specific needs of your prosthetic case.

Discover how to request your personalized component today!

Innova

You can request a customized component tailored to the specific needs of your prosthetic case.

Discover how to request your personalized component today!

Passepartout

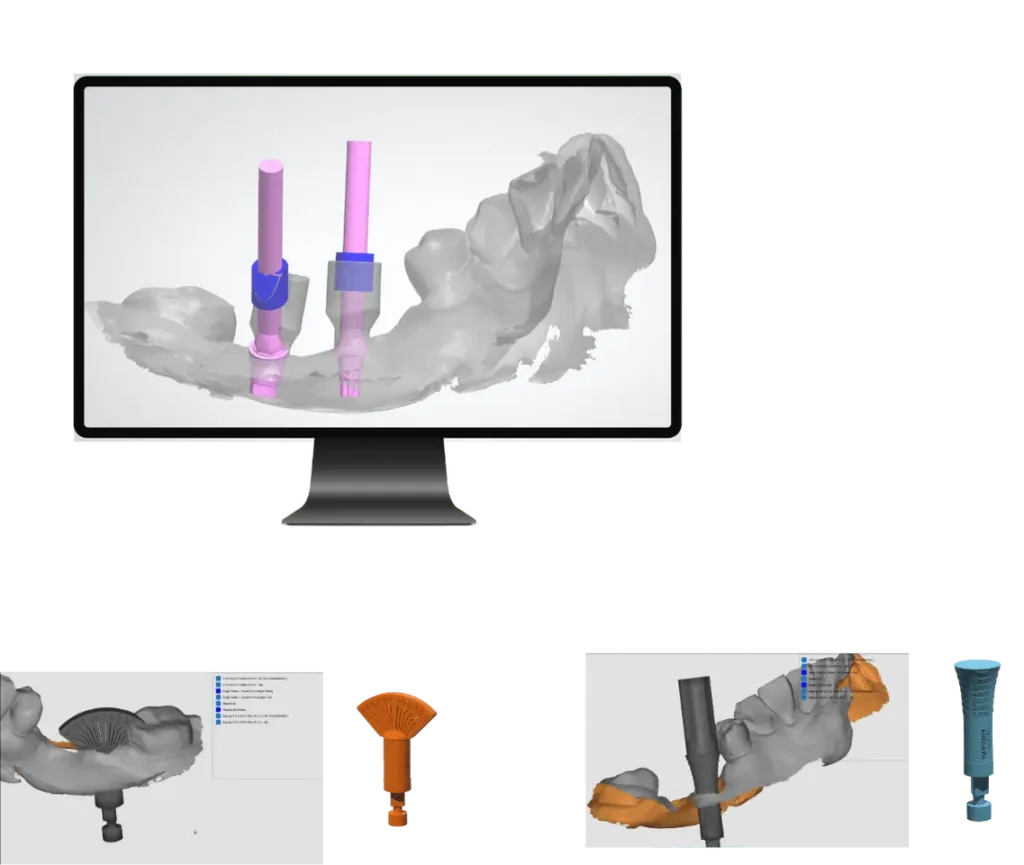

Features

■ Conversion:

Perform scanbody conversion in just 3 clicks!

Positioning the MUA:

Position the MUA directly from the intraoral scan

■ Customised digital prosthetic components:

Use the dedicated tools to assess optimal height, diameter and angle of customised MUA components

■ Efficency

Automatic generation of secondary scanbody on MUAS; Accurate creation of the necessary references for provisional prosthesis for immediate loading

Implant detector

Implant recognition in the patient’s mouth for:

- prosthesis creation

- the patient does not have an implant passport

PROTOCOL

What should you send to New Ancorvis?

- Abutment

- Analog

- Prosthetic Screw

1. Remove the prosthesis from the patient;

2. Degrease the inside of the implant well with alcohol/ethanol or orthophosphoric acid to in- crease the quality of the cast taken;

3. Proceed with impression taking;

*Concentration 35/37% using the product as per manufacturer’s instructions;

6 working days

Implantology

Scan Abutments

Locators

Surgical Kits

Guided Surgery

Bone Regeneration

Customised Implants

Facial Aesthetics

Customised Abutments

Straight and Tilted Abutments

Milled Dental Prosthetic Structures

Semifinished Dental Prosthesis

Analogues

Attachments

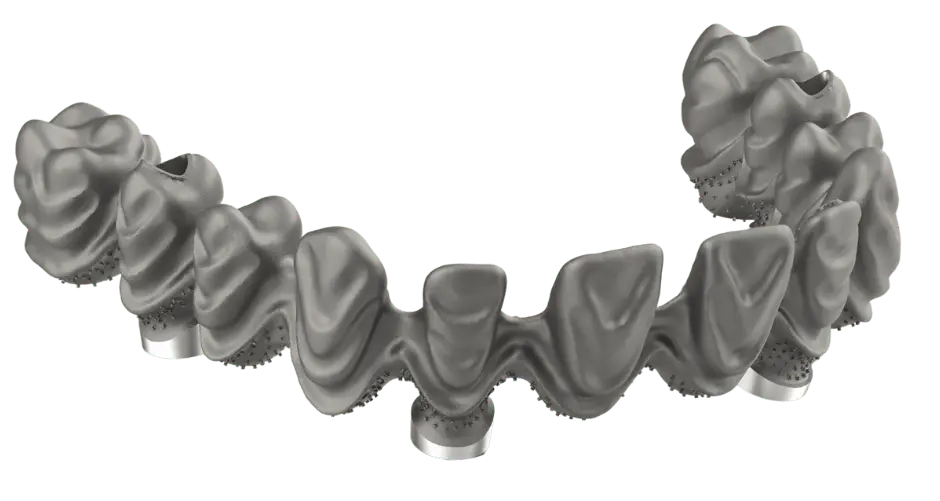

Printed Models

Zirconia Disks

Zirconia Blocks

EXCELLENTTrustindex verifies that the original source of the review is Google.